Product Description

Model NO.: JFA-CLPRCFSA Usage: Chicken Equipment Power Source: Electric Condition: New Rated Voltage: 380 V Manure(Water) Cleaning Rate: ≥95% Trademark: JINFENG Origin: China Type:

Chicken Cage Application: Pullet Chicken Certification: SGS, ISO9001:2008 Rated Power: 2.20-3.70 Kw Source Type: AC, 3-Phase Source Working Speed: 10~15 M/Min Specification: Hemp Rope Traction Type HS Code: 84362900

Manure Removal System For Layer Broiler Pullet Chicken Farm Use

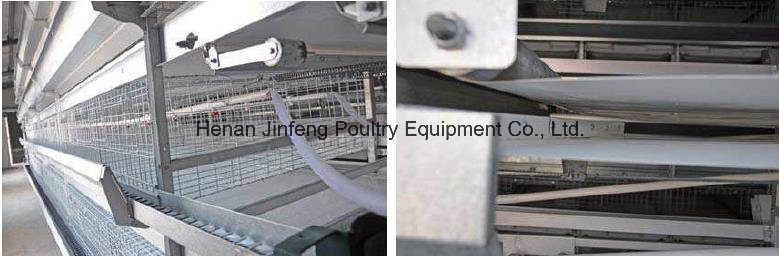

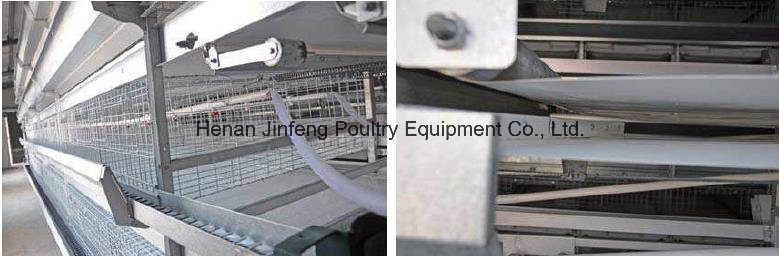

The Scraper Type Manure Collection System is designed for A frame cage systems which has manure pits under the cages. The manure dropping from the cages in the manure pits, and the manure scraper can collect the manure outside of the

chicken house. This system is popular design in China market or other countries who want to raise chickens on floor with cages.

The System Advantage special design for A frame

Cage System with manure pits under the cages, the various width of manure scraper are available lower cost and easily to operate by control panels Easily to install and make maintenance during the use solid structure and durable because of hot dipped galvanized manure scrapers and imported Nylon connection hemp ropes this system can be used in different A frame cage systems as layer, pullet, broiler and breeding chickens in close or open house saving more labor works and cleaning the chicken house inside immediately in order to control the ammonia emission

The System Structure

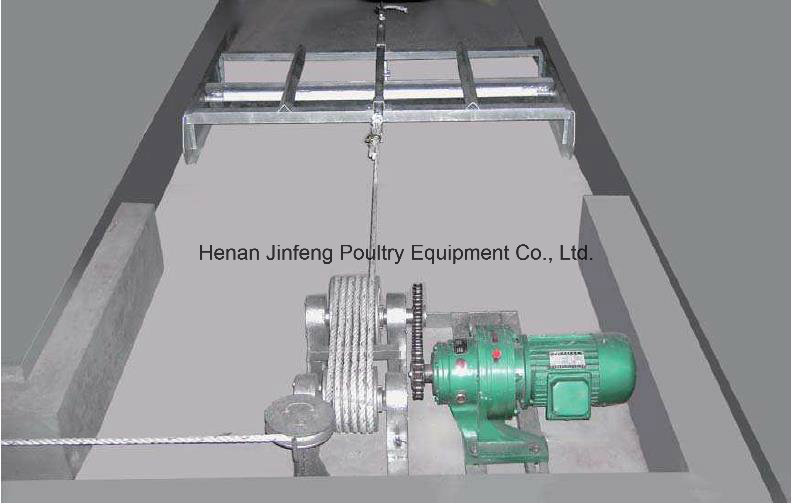

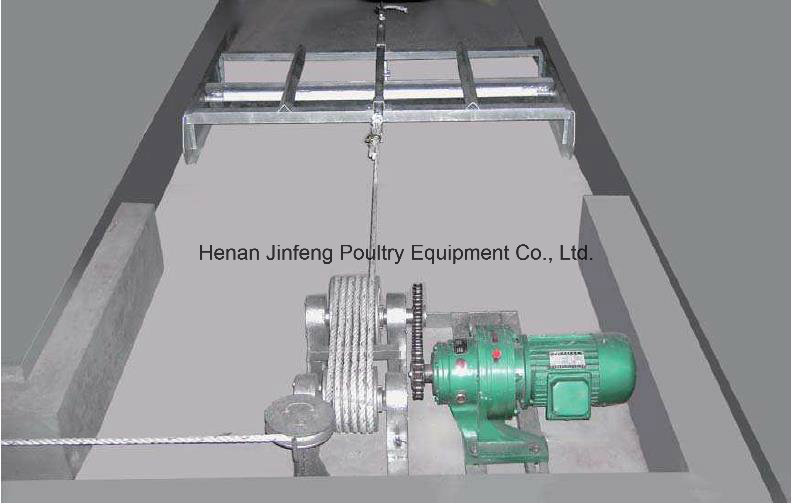

This system is consists of the frame, the motor, drive mechanism, traction rope (hemp rope, wire rope, chain), scraping dung plate, the anchor bolt and the electrical system. The motor power system is drove by Vertical machine what with the advanced cycloidal. The advantage of strong driving, low failure rate, long service life, low noise and it can reduce the influence of the noise on the chicken, then improve the rate of eggs production. The drive mechanism is consisted of the sprocket, chain, active rope wheel, and passive rope wheel. The sprocket is forded by 45 steel with high quality. The sprocket wheel strength and abrasion resistance of the sprocket is fully improved after processing by the advanced numerical control equipment, and then though the treatment of high-frequency hyperthermia .The chain is from famous brand (SHIELD) which has high tensile strength and good abrasion resistance. Scraper board is made of standard Q235 material. The pressing of surface by hot dipped galvanization. and for different length of house, we have different design as follows

Chicken house length ≥100 meters, one gear with one scraper, as the house is too long to clean the manure with large quantity outside of the chicken house.

Chicken house length≤100 meters, one gear with 2 or 3 scrapers, as the house length is short, and the gear has enough power to clean all 2 or 3 rows at same time.

The active and passive hemp ropes wheel is casted by the advanced casting process. The processing surface structure is processed by u-shaped slot, each slot is linked by the R arc, it reduces the friction and damage of the rope which imported from Italy with international quality.

380V three-phase power source dynamic output

| Item Name | Unit | Structure Specifications |

| Item No. | / | 9FQM-2H-1960-25 |

| Structure Type | / | Hemp Rope Traction Type |

| Rated Power | KW | 2.20-3.70 |

| Rated Voltage | V | 380 |

| Source Type | / | AC,3-Phase Source |

| The Most Working Power | N | 2800~3200 |

| Outline Dimension(L*W*H) | M | (1.0~1.5)*(0.4~0.7)*(2.50~4.0) |

| Structure Weight | KG | 150~350 |

| Manure belt Width/Thickness | MM | 1100~1800/1.0~1.50 |

| Height between cage and scraper | MM | ≥100 |

| Manure(water) Cleaning Rate | % | ≥95 |

| Working Speed | M/Min | 10~15 |

The Manure Removal System with Manure Belt is special design for H frame Cage System in close chicken house.it is consisted of transmission gear in front and back support frames in the two ends. And the manure belts which import from Italy which has international standard quality.

The System Advantages It can clean the manure with highest speed and effect. Automatic control at time , and you can set any time; Manure Belts made in Italy, high quality and durable. Connected with the transverse conveyor to the manure truck directly and no manure left in the farm, it means better environment for the chickens. All support frames are made of Aluminum Zinc plate and hot dipped galvanized board, durable and strong. The System Structure

This system is consists of the "H" support frames with power system in the two ends, support frames and protection boards on cage leg frames, manure collection belts, transverse conveyor and the synclinal conveyor, control panels.

1. When you press the starting button to collect the manure on belts, the fresh manure transports through the conveyor belt from the chicken cages to the belt and deliver to end of the end frames. The belts are fitted on the protection board which keeps the manure just inside of the manure belt, and the frames are supported by the two frames which just keep the belts static. The support frames can be from 1000--2000mm or wider as clients' requests. The manure belts will change its width and length according to the different width of cages and length of chicken houses. and 2-8 tiers can be produced as the h frame cage systems' height. 2. When the manure arrived at the end support frames, the manure on the conveyor belts will be cleaned by the scraper which fitted by springs to adjust the tightness. Then they fall automatically to the next conveyor belt, continues to transmit, until completes the entire channel's packing. Each has provided the emergency stop, guarantees breaks down when not serious damage. Electronic load sensor measures by the weight to adopt the belt ten dry channel's excrement quantities, thus in the coordinated chicken coop eliminates the manure conveyor belt and the dry conveyor belt speed through two sides of rotation opposite worm bearing adjuster. 3. The transverse conveyor belts usually 600mm wide and the length is 1000 mm longer more than the chicken house width. the manure will delivered to the synclinal conveyor and fall down the manure collection truck and move outside of the chicken farm..

Certification :

1. Iso 9001 quality control system .

2. Steel Structure Construction Qualification Certificate Grade

Our factory :

1. Professional steel structure manufacturers since 1989.

2. Professional

Poultry Equipment manufacturers since 1989

3. 2, 0000 sqare meters workshop for steel structure

Excellent service we can offer :

1. Poultry house site selection;

2.Light steel structure Poultry house design and construction;

3. Poultry equipment installation and test ;

4. Breeding trainning for operation workers

If possible, you can also add my phone number(86-188-39966163) for more details.

Contact us if you need more details on Manure Removal. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Battery Breeding Cage、

Farm Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : A Type Automatic Cage Rearing System